The construction industry in Singapore is increasingly focused on improving productivity while maintaining strict compliance with Environmental, Health, and Safety (EHS) standards. Managing EHS effectively is not just about safety—it's a critical driver of productivity, and centralized EHS management systems are becoming a game-changer in achieving this goal.

EHS management and productivity are intrinsically linked. Poor safety practices or environmental mismanagement can result in project delays, costly fines, or even site shutdowns. A well-structured EHS system ensures compliance, reduces workplace incidents, and creates a smoother workflow, ultimately enhancing overall efficiency.

Many construction companies still rely on manual or fragmented systems for EHS management, which can lead to:

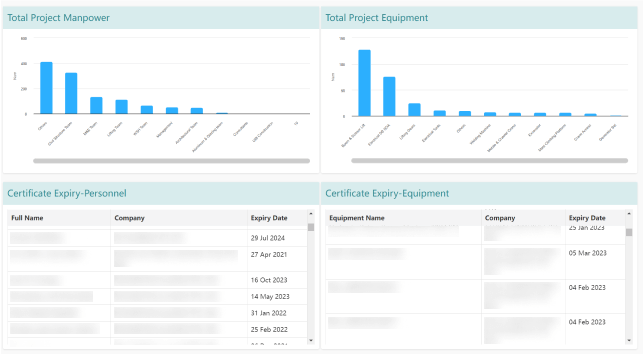

One of the persistent challenges in the construction sector is the complexity of Environmental, Health, and Safety (EHS) management, particularly between main contractors and subcontractors. Traditionally, EHS processes involve cumbersome paperwork, manual tracking, and disjointed communication. Main contractors often struggle to obtain up-to-date documentation from subcontractors, such as manpower and equipment certifications. Subcontractors, in turn, face difficulties keeping track of certification expirations and ensuring compliance across multiple projects.

This lack of a centralized system leads to inefficiencies, missed deadlines, and potential compliance risks, ultimately hindering productivity and collaboration across stakeholders.

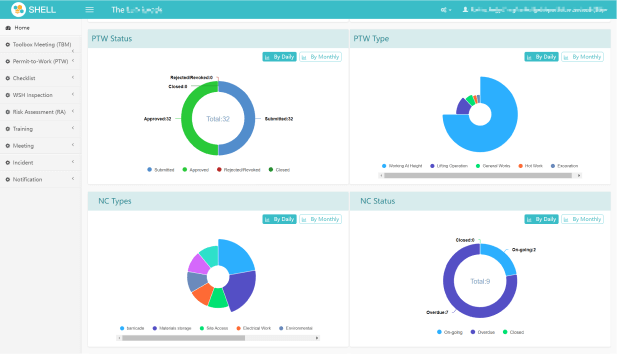

BES Shell,an EHS management solution tailored for Singapore's construction industry, acts as a unified solution to existing challenges by streamlining EHS management and fostering collaboration among all stakeholders involved in construction projects.

When a main contractor uses BES Shell in a project, they can create free accounts for their subcontractors, enabling seamless document management. Subcontractors can upload manpower and equipment certifications directly into the platform, ensuring all necessary documentation is easily accessible and up-to-date.

Additionally, if subcontractors are involved in multiple projects using BES Shell, they can conveniently reuse the same documents, eliminating redundancies and saving a significant amount of time.

By integrating EHS functions into a single platform, main contractors will benefit greatly from the reduction of manual effort, a fuss-free way to ensure compliance, and also actionable insights from project dashboards through real-time updates. This allows main contractors to stay focused on delivering projects efficiently and on time.

Since 2015, BES has been committed to transforming the construction industry through innovative solutions that streamline processes—not just in EHS management but across various facets of construction. BES continues to lead the way in driving digital transformation for a more efficient and sustainable industry.

Centralized EHS management is more than just a tool for compliance—it's a strategic enabler of productivity. By streamlining processes, improving safety, and fostering collaboration, it helps construction firms achieve their goals more efficiently while maintaining the highest standards of safety.

Is your company ready to embrace the future of EHS management? Solutions like BES Shell are here to drive your productivity to new heights while ensuring compliance and safety across all your projects.